Lubrication

Keeping things moving smoothly

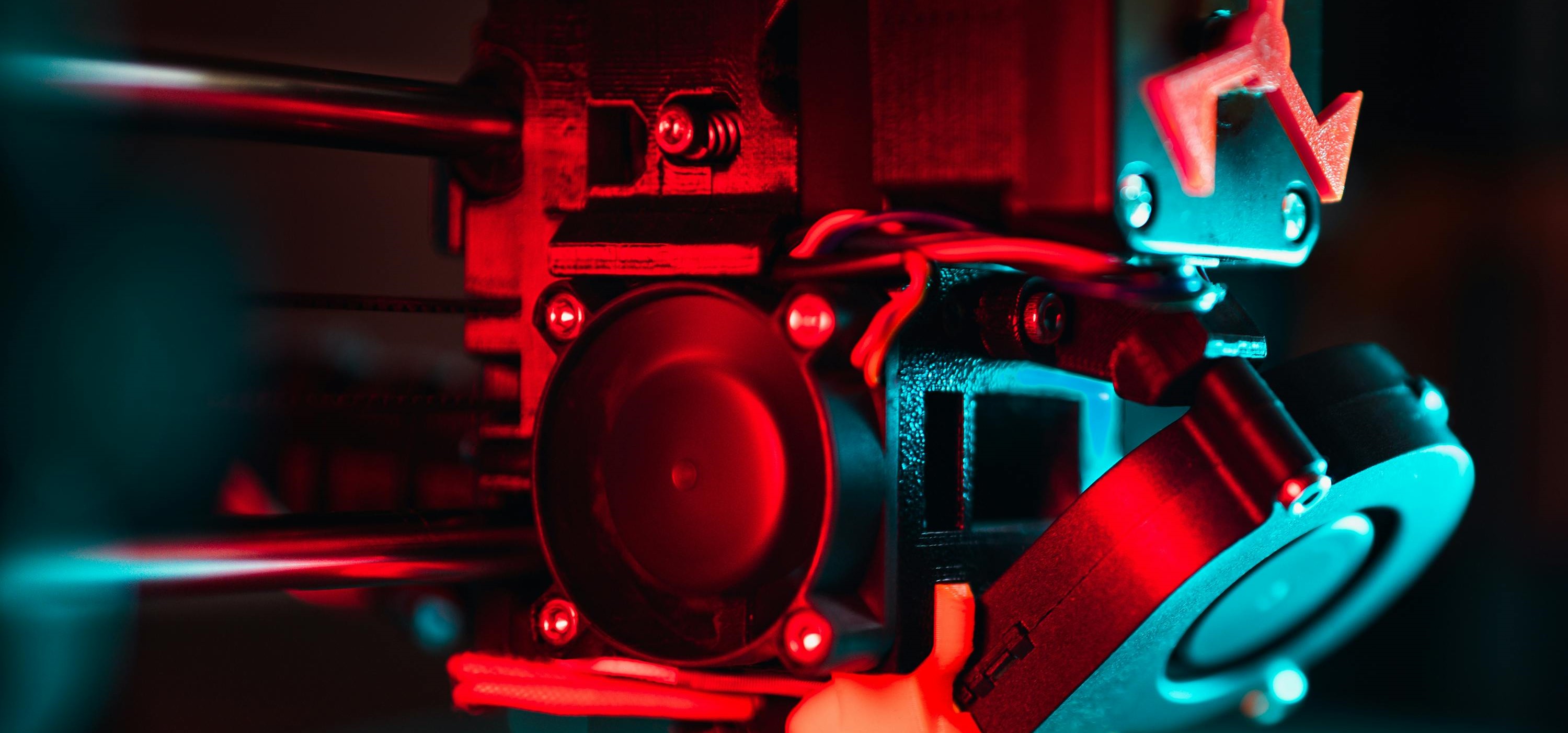

One of the things that you will be doing most often is lubricating the rails of your printer. Lubrication ensures that your machine can function properly, which is crucial for dimensional accurate and visually appealing prints. There are two main ways to lubricate the rails and bearings of a printer. Many manufacturers recommend using grease, which is thicker and longer lasting than oil. Grease can also include additives that preserve your moving parts, at the cost of being much more difficult to apply. On most printers that use grease for the bearings, in order to apply new lubricant you must disassemble the machine down to the level of the rails and apply the grease directly to the bearings.

The most common method of lubricating the rails on a printer is to use an oil applied to the rails, and then spread across the entire length my moving the print head or print bed back and forth through the entire range of travel. This can be done either by pushing the part by hand with the stepper motors disabled, or by using the controls of the printer to move the parts back and forth. While this method is much easier to use since it doesn’t require any of the printer to be disassembled, it does have to be done more frequently. I lubricate the rails of my printer once a month with sewing machine oil, which is an oil that is designed for use on small moving parts that are exposed to the air. There is an excellent guide on 3d printer maintenance by 3dMusketeers on YouTube, which I have obtained permission to use here. I will link the video here, starting at the section on lubrication.